Engaged in the clothing industry for 20 years.

European start-up offers customised shirts for the Indian market

Over 1.4 billion people, a growing middle class with rising disposable income. India, the world’s largest democracy, attracts many investors because of its large market size, especially when it comes to clothing. But much of the sector is unorganised, the infrastructure leaves a lot to be desired, and even the smallest task can take time…

The Shirt Dandy is a start-up that has taken the plunge – the Austrian company manufactures custom-made shirts for men in India. A daring venture or a clearly calculated risk with a good chance of success? FashionUnited spoke to Thomas Hebenstreit, founder of The Shirt Dandy, about the idea behind the start-up and the challenges and opportunities of the Indian market.

Mr. Hebenstreit, in India, the land of customised and quick tailoring, wanting to sell men made-to-measure shirts – isn’t that like offering refrigerators in the Arctic?

Yes, perhaps at first glance. And I have to admit that we had initially planned the more traditional business model: produce in India and then sell in Germany or Europe. But the supply chain is long and therefore not really sustainable. The logistics were also difficult.

So you thought, why not sell in India?

Something like that. India has a high population density and a high growth rate of almost 9 percent. In addition, the purchasing power is increasing. You don’t find this combination everywhere.

But still, India is not an easy market, you have to understand it. How did you decide on India?

I knew the country. I come from the business area, management and finance and lived in Delhi for some time in 2022. Now The Shirt Dandy has its headquarters in Gurgaon near Delhi and employs seven people there.

How does ordering via The Shirt Dandy work exactly?

Customers can make an appointment with our specialist via the website, who will then make a home visit and take the measurements in about 20 minutes. They can then also choose the fabric and benefit from the specialist’s expertise. The finished shirt is then delivered within 7-10 days.

That is quite fast.

Yes, because several employees work on one shirt in a multi-step process.

What if the finished shirt does not fit exactly?

If the first shirt doesn’t fit, it gets altered very quickly; immediately in case of minor adjustments, otherwise within a few days. That was one reason why we decided against the European market – in Austria, for example, you have to wait three months for such a change, which is simply too long. In addition, the peoplepower you would need for taking measurements is expensive.

For returning customers it is even easier – they can access their stored data by customer number and enter the desired details for their new shirt.

What if a customer prefers contactless ordering?

I’m glad you asked – that will be possible from the end of October with the relaunch of our website. Customers will then be able to take a photo or photos of themselves and upload them via the WebApp. None of these photos will be saved, by the way.

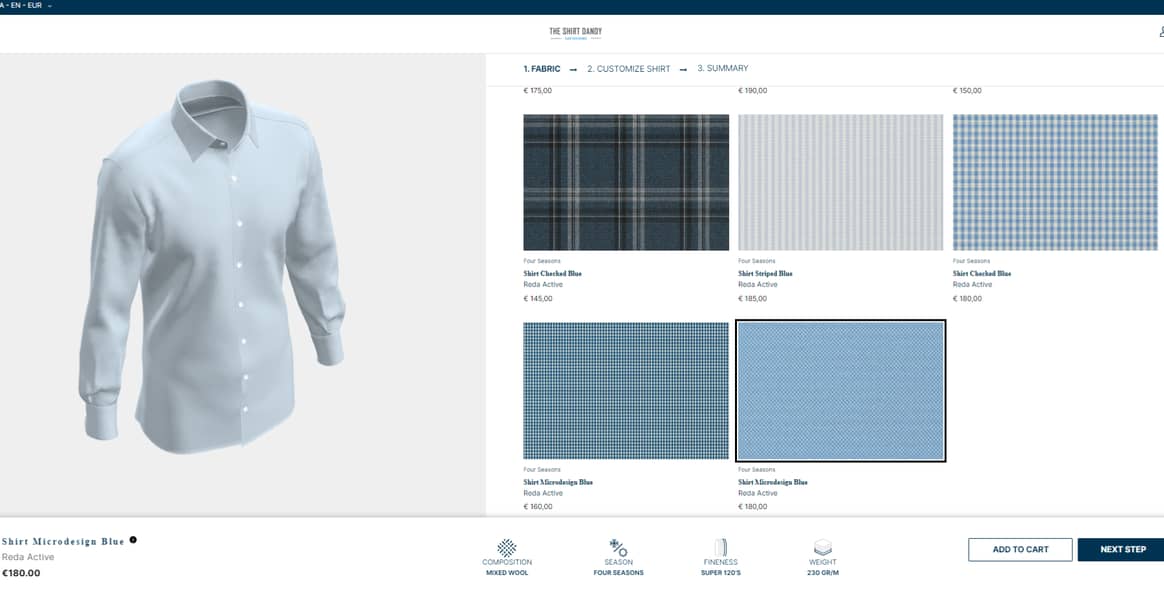

Using our first 3D configurator, also launched in October, in collaboration with the Italian company Reda, the exact measurements will then be created and the process will continue in the same way as taking measurements in person.

How much does a custom-made shirt like this cost?

The Shirt Dandy is very competitive when it comes to prices. It starts at 3,500 rupees (about 40 euros, 42 US dollars or 35 British pounds) and goes up to 12,000 rupees (about 137 euros, 144 US dollars or 118 British pounds), depending on personalisation, for example with a monogram, a certain collar, cuffs, and the like.

This individualisation is also an incentive; after all, no one wants to be like anyone else. The trend towards increasing individualisation coincides with the technical progress that makes this possible. So for us, this is the ideal time to enter the market.

Talking about competition – Indian men are quite choosy when it comes to their shirts, whether it is for the office, leisure or formal occasions.

Established Indian brands such as Aditya Birla’s Louis Philippe and Allen Solly, Tata’s Westside and Raymond, Park Avenue, ColorPlus and Parx by the Raymond Group are popular, as is US brand Arrow, distributed by Arvind Lifestyle Brands.

Yes, that is true, but we offer a premium product at a competitive price, plus free lifetime changes. So if someone grows taller, loses weight or gains weight, he can have his shirt altered at no cost.

That kind of offer is unusual indeed. You mentioned sizes – do you work with certain size specifications?

No, everything is made-to-measure, so there are no size templates.

Which is more democratic and goes into the area of body positivity – no one has to squeeze into limited size templates from XS to XL, for example.

Do you think there could soon be followers, somebody copying your concept, i.e. producing for the Indian market with European know-how?

That is not so easy – the way of working in India is quite different. You have to know this, you have to have been here before. It is also very important to have the right local partners.

That is the keyword – where are the shirts manufactured?

We produce in a factory in Bangalore. I have personally visited it and checked everything. It is quite advanced, better than average. For example, almost the entire energy suppy is covered by solar energy, which comes from solar cells on the roof of the factory. Also, the entire value chain is in India, which was very important to us, including the raw material.

What raw material do you use for the shirts?

Indian cotton but also Tencel from Lenzing and bamboo, which grows back quickly. We pay attention to environmentally friendly fabrics and deliberately avoid polyester blends. We attach great importance to sourcing locally, producing locally and selling locally.

That sounds sustainable, as does ordering on demand.

Yes exactly, we follow a purely made-to-order model, so in that sense there is no inventory, as customers only buy something when they need it. Made-to-measure products also fit better, so customers generally need to buy fewer shirts. In addition, each of our products is equipped with information about which fabric was used, what composition it is, what colour. This makes it easier to recycle later.

Customers also have the option to return their old clothes and receive a 5 percent discount on their next orders.

And how would potential customers hear about The Shirt Dandy?

We advertise on social media – on Instagram and Facebook, for example – and target our groups very specifically.

We are also planning a first store in Gurgaon. But we are still in the evaluation phase and think that this will become a reality only in the first half of 2024.

What else does the future hold for The Shirt Dandy, shirts for women perhaps?

Yes, that is possible, especially in the area of shirts from companies as an employee benefit to all employees.

We are also planning to get fully certified soon to officially prove our efforts in the areas of sustainability, social responsibility and fair working conditions. In terms of turnover, we are hoping for one million euros by 2024.

We will evolve the range within 24 months – for example, expand to chinos and polos, also more festive clothing, but nothing traditional. In terms of colours, we will keep the tried and tested – so for shirts, white, blue and pink.

Yes, that’s where the Indian market differs from the European market – for Indian men, pink is a natural part of their wardrobe.

Finally, the question with which one usually starts such a conversation – what prompted you to start The Shirt Dandy?

The Shirt Dandy was born out of a personal need – spending three hours looking for a good and well-fitting shirt is simply not possible, so we wanted to remedy that.