Engaged in the clothing industry for 20 years.

Saving clothes from landfill, two companies leading the way in war on waste

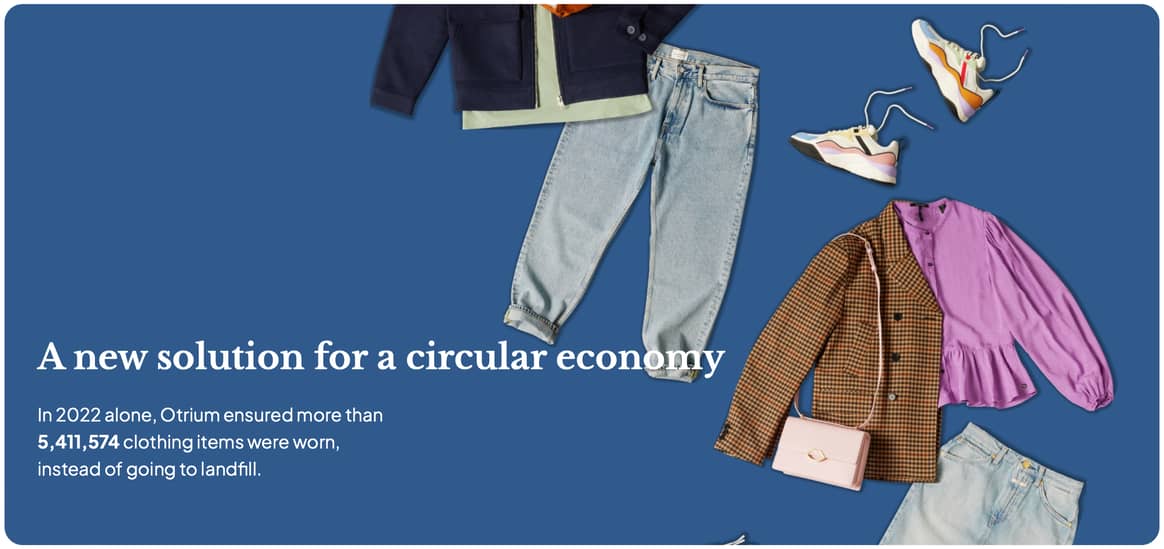

Two standout companies from Fashinnovation’s 9th Worldwide Talks in September are determined to show us the value of what we already have. One works to ensure all discarded clothes are recycled, the other strives to make sure all unsold clothes get worn. The result is that neither old nor new clothing will end up in landfill, not on their watch. Milan Daniels, co-founder and CCO of Otrium, a company that sells unsold, excess inventory from brands, (the tags are still on the items), earned the accolade of the “most innovative of 2022” from Fast Company and raised 120 million dollars ahead of Otrium’s US launch. Uddhav Bagrodia, President and co-founder of Wastewear Inc. takes clothing at the end of its life cycle, breaks it down to fiber and creates new clothing without using any dyes or pollutants, thereby forcing our industry to question the need for Pantone color standards. FashionUnited interviewed Daniels and Bagrodia about their individual approaches to lengthening the life cycle of fashion.

Milan Daniels, co-founder and CCO of Otrium

Why does Otrium stand out?

When it comes to excess inventory, historically, the only option has been for brands to sell products to a wholesaler or clearance distributor for pennies on the dollar. At Otrium, however, thanks to our technology we’ve been able to pioneer new and better solutions for brands and consumers alike. We give brands an elevated, highly-scalable digital platform paired with the right data and tools to smartly connect with fashion-lovers around the world—an environmentally-friendly, adaptable solution that was previously unavailable.

What specifically motivated you to found Otrium?

Prior to Otrium, my co-founder Max and I started a DTC streetwear brand, which really opened our eyes to the amount of excess inventory that fashion brands produce—and subsequently the lack of viable solutions for brands to dispose of unsold items. As we looked into it more, we realized that while 1 in 7 items of clothing produced never find a home, there had been little to no innovation in the space, which inspired us to create a solution ourselves and is how Otrium came to life.

What is the future for Otrium?

Fashion is truly an incredible industry—it is deeply personal, an art form, as well as an absolute need—but it’s currently trapped in a broken cycle of overproduction. Looking ahead we’re focused on changing the way fashion is produced and sold by offering brands a better solution to recover the value of their unsold items, as well as directly contributing to pioneering new consumer shopping behaviors and paving the way for inventory to find a home instead of ending up in a dusty warehouse or dumped in landfills.

What are the challenges in running Otrium?

At Otrium, we envision a world where all clothing produced is worn and while we currently work with 450 brands on the platform and are growing everyday, there is still a lot of work that needs to be done. Excess inventory is a 200 billion dollar commercial problem for brands and has become a growing concern not only for the fashion industry, but for the planet as a whole. We’re dedicated to leading the way in making a meaningful shift in the trajectory of this problem, and every day our team works to identify how we can continue to improve and strengthen our efforts even further.

Uddhav Bagrodia, President, Wastewear Inc.

Why does Wastewear stand out?

We are diverting textile waste away from landfills, reclaiming for new products post-industrial cotton waste from surrounding factories, that might have been left over from a large production run or from the cutting room. We turn that waste into basic items and uniforms for corporations, colleges, and government offices but we don’t use any dyes in our production so that saves huge amounts of water and obviously increases our sustainability.

What specifically motivated you to found Wastewear?

I grew up in textile manufacturing in India in the family business, and I could see from an early age the waste associated with it. Five years ago we started working with recycled materials from used garments that had reached the end of life to make yarns. Sorting garments is a mechanical process, no chemicals are used, we shred the garments after removing buttons, zippers, cut it down into smaller pieces, then feed it into a machine that pulls apart the fabric into fiber form, and ensure it’s good enough to spin, then we make yarn with it. We’re New York-based, source local textile waste, and currently all our customers are in the US, while manufacturing happens in India with the family business as a partner.

What is the future for Wastewear?

The concept of circularity is essential to the future of the industry. We’re not using any virgin materials, just promoting the beauty of what we have. It’s not about replacing what’s already there but looking at these as new materials. We don’t compare mycelium to silk or vegan leather to real leather, neither should recycled textiles be compared to virgin material, but instead evaluated on their own merit with their own distinct properties. These materials can complement what is already going on in the industry. What’s stopping a brand like Ralph Lauren who offer twelve colors of polo shirts to have two of them made out of recycled cotton? Down the line that offsets the manufacturing costs of the other ten colors.

What are the challenges in running Wastewear?

We source cotton waste that has been color sorted and don’t use any dyes. It’s something that can be considered a limitation but I don’t like that word. It means we can’t work to an exact Pantone shade, but our products are basic essentials and we stick to traditional color palettes. It’s easy for us to work sustainably within those parameters, working with large batches, spinning anywhere from one ton of fiber, so that entire batch will have the same color. The next batch might have a slightly different hue. But if we did a huge run of green in a non-standard shade, there might be some variation. We don’t see this as a limitation, because there is more than enough black or white waste out there and there’s no risk that the public will stop requesting those colors. The challenge is responding to what the customer expects or at least what the brand believes the customer expects. In the case of recycled polyester we have reached a point where the material is cost effective and easily used. This is not the case with recycled cotton but we will get there. And that will go hand in hand with customers accepting our material

s non-dyed state.